A countersunk head self-tapping screw is a fastener with a unique head design that allows it to sit flush with or slightly below the surface of the material it is driven into. The head shape is conical, which enables the screw to "sink" into the material without protruding, providing a clean and aesthetically pleasing finish.

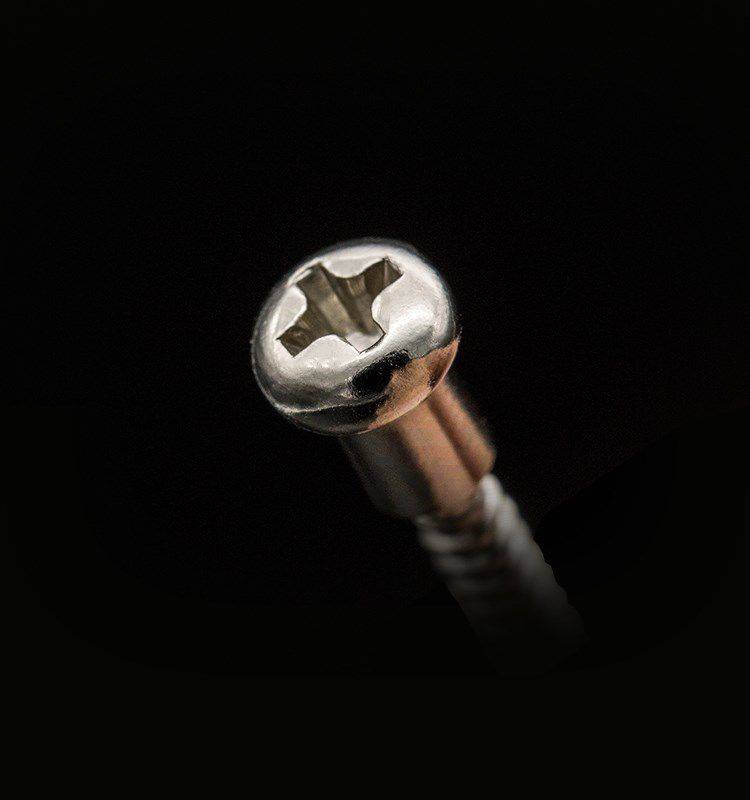

The "self-tapping" feature of the screw refers to its ability to create its own hole as it is driven into the material. This eliminates the need for pre-drilling, making the installation process faster and more efficient. The threads of a self-tapping screw are specifically designed to cut into the material as the screw is driven in, creating a secure hold without the need for additional tools.

Key Features of Countersunk Head Self-Tapping Screws

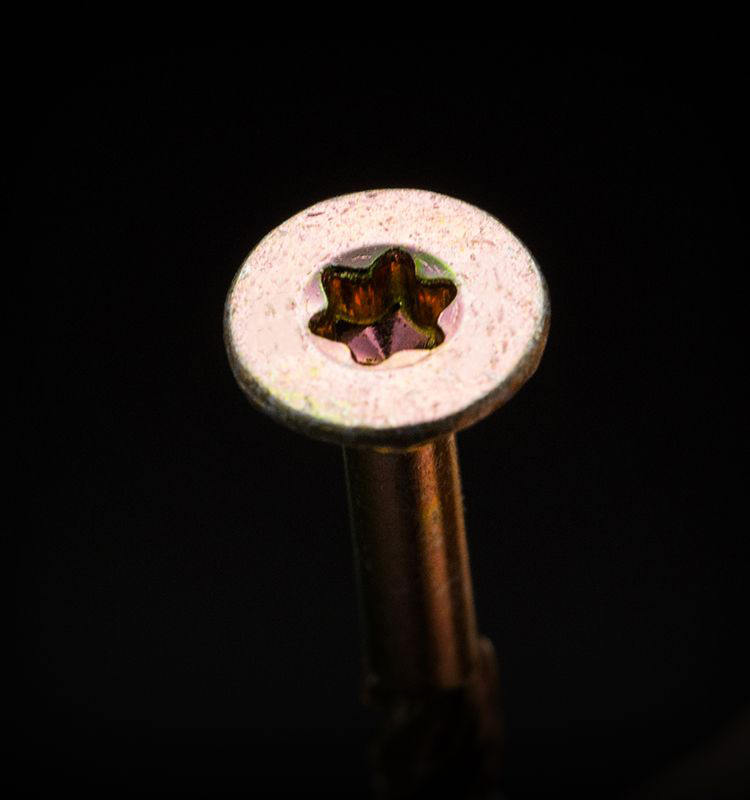

Countersunk Head Design: The most distinctive feature of this type of screw is its countersunk head. The angle of the head is usually around 82° or 90°, allowing it to fit neatly into a countersunk hole in the material. This helps achieve a smooth surface finish, which is essential for both aesthetic and functional reasons.

Self-Tapping Threads: The threads on these screws are designed to tap into the material as the screw is inserted. This means that they can be used on materials like wood, plastic, or metal without requiring a pre-drilled hole, which saves time and reduces labor costs.

Variety of Materials: Countersunk head self-tapping screws are available in various materials, including stainless steel, carbon steel, and zinc-plated steel. The material choice depends on the specific application and environmental conditions, such as exposure to moisture, corrosion, or high temperatures.

Applications: These screws are commonly used in woodworking, metalworking, and plastic fabrication, where a flush finish is desired. In addition, they are often used in applications where vibration resistance and a secure, long-lasting hold are required.

Ease of Use: Self-tapping screws, including countersunk head types, are designed for easy installation. They can be driven in using a power tool or manual screwdriver, making them accessible for both professionals and DIY enthusiasts.

Benefits of Countersunk Head Self-Tapping Screws

Aesthetically Pleasing: The countersunk head ensures that the screw will sit flush with the surface, which gives a neat and clean appearance. This is especially important in applications where the finish is visible and important for the overall look, such as in furniture or electronics.

Time Efficiency: The self-tapping feature eliminates the need for pre-drilling, speeding up the assembly process. This is particularly useful in mass production environments where time and cost savings are critical.

Strong and Secure: Countersunk head self-tapping screws provide a strong and reliable fastening solution. Their ability to tap directly into materials ensures a secure hold that can withstand various stresses, including vibration, tension, and shear forces.

Versatility: These screws are versatile and can be used in a wide range of materials, including soft woods, hard woods, plastics, and metals. The thread design can be optimized for different material types, making them suitable for diverse applications.

Reduced Risk of Material Damage: Since self-tapping screws create their own hole, there is less risk of cracking or damaging the material compared to using traditional screws that require pre-drilled holes. This makes them ideal for delicate or thin materials.

Common Applications

Furniture Manufacturing: Countersunk head self-tapping screws are frequently used in the assembly of furniture. Their flush finish makes them ideal for joining panels and parts where the appearance is important, such as in cabinetry and desks.

Electronics: In electronics, these screws are used to assemble devices, components, and enclosures. Their ability to create secure, vibration-resistant connections without damaging sensitive components is essential.

Automotive: Countersunk head self-tapping screws are used in automotive applications for fastening metal parts, plastic trims, and interior components. The self-tapping feature ensures quick and secure installation, especially in areas where access is limited.

Construction: These screws are often used in construction, particularly in applications where securing sheet metal or wooden structures is necessary. The countersunk head provides a smooth finish, ensuring that the surface remains even and secure.