Drill Tail Screws are used for a variety of applications in construction, especially to fasten metal plates. These screws are more effective than conventional screws in the same area, as they can be drilled and tapped directly on the plate. They also have a better holding power than other screws and are easier to operate. They are also easier to clean up and work with than traditional screws, as they have a point that allows for the removal of drilling chips.

The first thread 70 is spirally disposed in the lower section 66 of the straight rod portion 64 and includes a plurality of threads 74, each having a lower cutting surface 76 on the locking side (facing the drill tail 54) and an upper cutting surface 78 on the exit side (backward drilling end 54). Each of the threads 74 has a pitch (P) and each of the threads 74 extends between the cutting line 80.

Each of the threads 74 has ridges (a) which are spaced apart from each other by a distance (b). The first thread 70 is spirally disposed with a first pitch (P1) between adjacent threads 74, and the second thread 72 is spirally disposed with a second pitch (P2) that is larger than the first thread P1.

Screws with pointed heads or drill tails, as they are known, are often used to fasten metal to wood and can be easily identified by their shape. These screws require fewer tools to operate, and can be drilled, tapped, and locked at one time, saving the user a lot of effort. They are also more durable and longer lasting than ordinary screws.

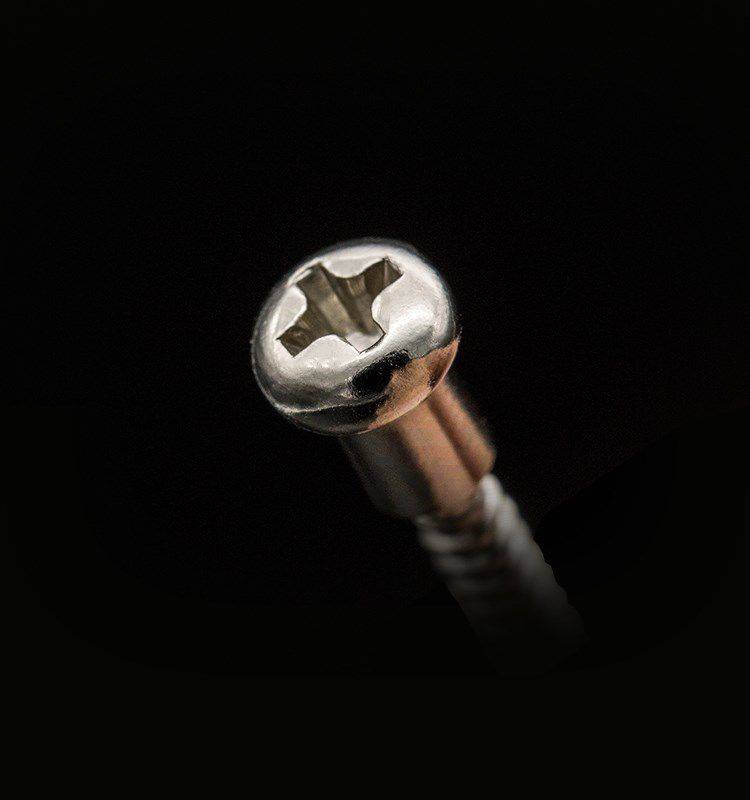

When using these types of screws, it is important to use the right bit for the job. Using the wrong bit can cause them to get stuck, or break off inside the head. The best way to avoid this is to use a slow, steady amount of power. In most cases, this will suffice, but in some situations, you may need to apply a burst of torque. This can be done by timing your pushing/pressure with the drill's rotation.

It is also important to ensure that the head of the screw is positioned correctly in relation to the hole it is being driven into. Keeping the head in the correct position will help to prevent it from breaking off in the hole, or being pushed backwards by the chuck of the drill.

The screws that are manufactured by Shenzhen Carter Hardware Products Co., Ltd are mainly processed by pickling and hot-dip galvanizing, and the finished screws can be packed in cartons or plastic bags according to customer requirements. The company's products are exported to countries around the world and are widely used in various fields. Shenzhen Carter is dedicated to providing quality hardware and services for all customers. Its main product categories include outer hexagon, inner hexagon, all kinds of nuts, flathead screws, U-shaped bolts, self-tapping nails, and expansion screws.