Why is a Thicker Gauge Important in Fiberboard Nails, and How Does it Contribute to the Performance and Durability of Fastening in Fiberboard Materials?

Fiberboard nails with a thicker gauge play a essential function in making sure the effectiveness, toughness, and reliability of fastening programs in fiberboard substances along with Medium-Density Fiberboard (MDF) and particleboard. The desire of a thicker gauge in those specialised nails is pushed via the specific characteristics of fiberboard and the need for greater preserving energy and balance at some point of installation.

1. Increased Holding Power:

One of the number one reasons for choosing a thicker gauge in fiberboard nails is to beautify keeping electricity. Fiberboard, being a dense and engineered timber product, calls for a more potent grip to prevent the fasteners from loosening or pulling out over time. The thicker gauge provides more tensile electricity and resistance to forces that might try to dislodge the nail from the fiberboard substrate.

2. Resistance to Withdrawal Forces:

Fiberboard substances, while long lasting, can be liable to withdrawal forces which could occur due to various factors consisting of vibration, temperature modifications, or structural hundreds. Thicker-gauge nails offer improved resistance to those withdrawal forces, making sure that the fasteners continue to be securely embedded in the fiberboard. This resistance is especially vital in packages in which the integrity of the connection is vital, such as in furniture manufacturing or carpentry.

3. Minimization of Nail Bending:

Thicker-gauge fiberboard nails show off greater stiffness, minimizing the hazard of bending all through set up. When operating with dense materials like fiberboard, a nail that bends effortlessly might not penetrate correctly or offer the vital balance. The improved rigidity of a thicker-gauge nail allows for a instantly and secure insertion, decreasing the probability of installation problems and selling a dependable connection.

4. Prevention of Splitting:

The thicker gauge in fiberboard nails additionally contributes to the prevention of splitting, a common issue whilst fastening dense substances. The increased thickness distributes the force more calmly over the surface area of the nail, lowering the pressure exerted at any given factor. This enables mitigate the threat of the fiberboard splitting or cracking throughout the insertion manner, ensuring a clean and intact connection.

5. Adaptation to Fiberboard's Structural Properties:

Fiberboard materials own unique structural traits that range from herbal wood. Thicker-gauge nails are designed to house these differences through providing a fastening answer tailor-made to the density and composition of fiberboard. This adaptation guarantees that the nails effectively penetrate and keep within the cloth with out compromising its structural integrity.

6. Long-Term Durability:

The mixture of elevated holding strength, resistance to withdrawal forces, prevention of splitting, and adaptation to fiberboard's structural properties together contributes to the long-term sturdiness of fastening applications. Thicker-gauge fiberboard nails help create strong connections that resist the take a look at of time, making them appropriate for a wide range of packages in industries consisting of production, woodworking, and fixtures manufacturing.

In conclusion, the choice of a thicker gauge in fiberboard nails is a strategic choice aimed toward addressing the particular challenges posed by dense and engineered timber substances. This design feature ensures no longer best the immediate effectiveness of the fastening method but additionally the long-lasting overall performance and reliability of connections in fiberboard packages.

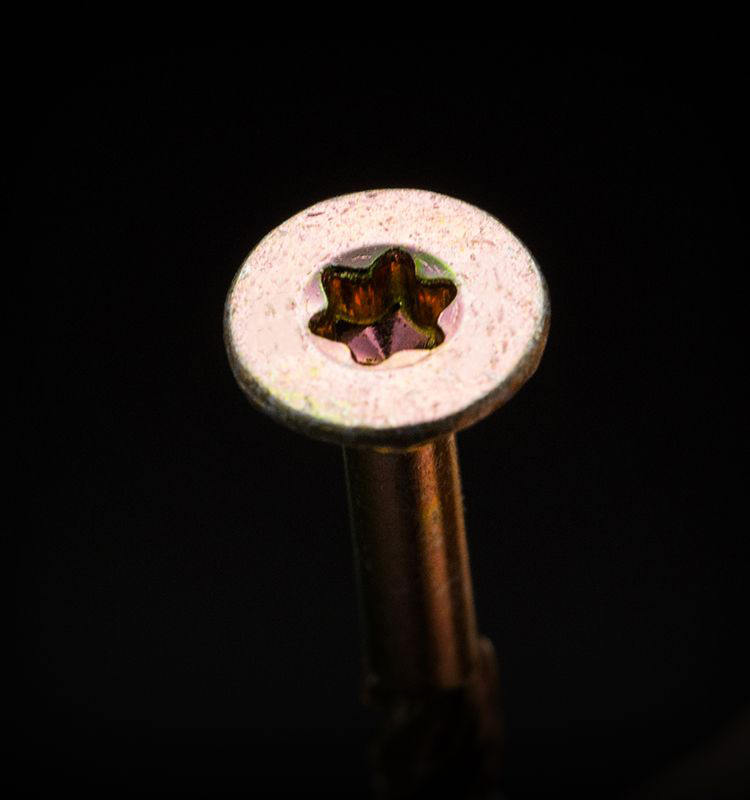

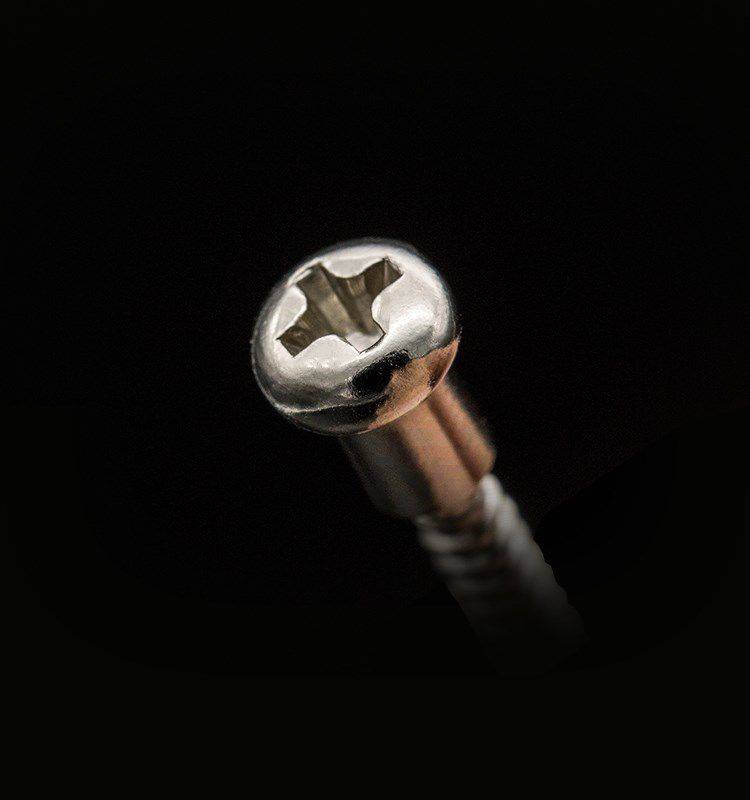

Square grooved coarse tooth fiberboard nails

Square grooved coarse tooth fiberboard nails